Alternative energy

Alternative energy usually generates by solar cells, wind turbines, tidal power plants, etc. Unfortunately they have not been widely spread in our country because of relatively low natural gas prices and long payback periods of projects, as a result. These areas, our company is not engaged. But there is a new areas of energy, for example, as alternative water-team technology ...

What is the ORC-technology

If in the cycle as the working fluid is not used water as usual, and LBWF - low boiling working fluid is used, such unit will work on organic Rankine cycle (ORC) technology. LBWF is an organic or synthetic material with a low boiling point. Such installations are used for obtaining energy from the different sources of heat and also from low potential heat with temperature about 100 °C (geothermal power plants) .

LBWF is an organic liquid fluid for example pentane С5Н12. Pentane is liquid at +36 ˚C (at atmospheric pressure) after +36 ˚C changes into a gas. Examples of other low boiling working fluids: hydrocarbons (butane, isobutane, cyclopentane, propane), freon (R134а, R245fа), ammonia, toluene, silicone oil, and CO2 at high pressure, or a new synthetic substance Novec 649 development of 3M, known by brand "Scotch", etc. Last fluid compare with pentane it is non-flammable, inert, non-conductive and environmentally friendly.

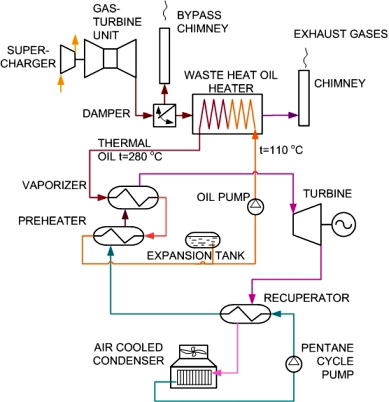

Typical scheme of power plant (heat recovery) based on organic Rankine cycle is shown in the figure below. The main parts of it: waste heat oil heater (WHOH), turbine with an electric generator and different heat exchangers (evaporator, heater, recuperator and air condenser).

The exhaust gases from the gas turbine through a

damper (diverter) enter the thermal oil boiler. Diverter makes it possible not to stop operation of the gas turbine,

if necessary the recovery system halting. In the primary circuit of the system is used thermal oil.

This is due to the fact that most LBWF - combustibles, and the temperature of exhaust gases in modern gas turbine reaches 500

˚C. Thermal oil is more resistant to high temperatures. Thermal oil enters

WHOH in temperature range 90 ÷ 130 ˚C, outlet from it 280 ÷ 310 ˚C.

The exhaust gases from the gas turbine through a

damper (diverter) enter the thermal oil boiler. Diverter makes it possible not to stop operation of the gas turbine,

if necessary the recovery system halting. In the primary circuit of the system is used thermal oil.

This is due to the fact that most LBWF - combustibles, and the temperature of exhaust gases in modern gas turbine reaches 500

˚C. Thermal oil is more resistant to high temperatures. Thermal oil enters

WHOH in temperature range 90 ÷ 130 ˚C, outlet from it 280 ÷ 310 ˚C.

Hot oil transfers heat to the LBWF in the preheater and the evaporator. Working fluid transform from liquid in

to gas and then

it is directed to the turbine.

Organic gas expands in the turbine. Turbine rotates generator shaft at a

speed of 1500 rev / min and electricity is generated.

After turbine LBWF enters the recuperator and then into the air

condenser. After the condenser, it is sent to pump and after it to the

heater where it is heated up to 220 ÷ 250 ˚ C and then directed to the

turbine.

In the case of using in the main loop supercritical

CO2

an intermediate thermal oil circuit is not required,

CO2 is sent

directly into the boiler.

Pentane equipment usually instal in the open air because of explosion

safety. Thus, in case of leakage of the working medium

avoids the formation of explosive concentrations of vapor. The figure

below shows a typical layout of pentane heat recovery system for a gas

turbine exhaust gases.

Pentane equipment usually instal in the open air because of explosion

safety. Thus, in case of leakage of the working medium

avoids the formation of explosive concentrations of vapor. The figure

below shows a typical layout of pentane heat recovery system for a gas

turbine exhaust gases.

Comparison of power plants using steam and organic Rankine cycle.

In addition to basic equipment, steam boiler and turbine in

steam heat recovery system there are a lot of accessories

equipment: cooling device (cooling tower) for a steam turbine, deaerator,

water treatment system, feed pumps, condensate pumps and circulators.

All of this is connect to each other the numerous pipelines: feed, steam pipes, circulation, condensation,

chemically treated, raw water, process water. In all of these pipelines

have a huge amount of regulating and shut-off valves, both manual and electric.

To prepare launching of the basic equipment,

steam pipes should be heat. Huge amount professionals open manually controlled

valves, pipeline valves, air vents and after warming up - close. Preparing for the launch takes several hours.

All this complicates control system and maintenance of steam turbine power plant.

To prepare launching of the basic equipment,

steam pipes should be heat. Huge amount professionals open manually controlled

valves, pipeline valves, air vents and after warming up - close. Preparing for the launch takes several hours.

All this complicates control system and maintenance of steam turbine power plant.

The big danger is a negative

temperature, particularly for cooling towers. Furthermore, cooling of

the condenser requires a large amount of process water.

The figure shows, "Ormat" pentane installation that utilize heat of GCU (gas compressor unit)exhaust gases at the compressor station.

Advantages of the pentane installation compared with steam power

plant are in the following:

- No water is needed for the

technology

instead not freezing liquids are used: pentane, thermal oil;

- There is no complicated steam

turbine equipment (boilers, turbines, chemical treat, deaerators, etc.);

- There is no main building, as all

the equipment is installed in the open air;

- The operating personnel doesn't

require, everything is in automatic mode;

- All systems operate safely up to

the outside temperature minus 50 ˚С;